| News | Home > News |

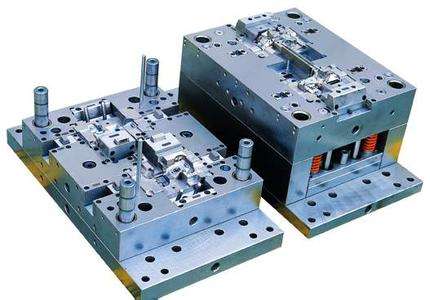

| How to design molds for plastic mold manufacturers |

| Release date:2018/12/28 13:18:28 |

The content expressed in this article is How to design molds for plastic mold manufacturers, please feel free to contact me.

How to design molds for plastic mold manufacturers

How to design molds for plastic mold manufacturers, the mold temperature is high, the molten material cools slowly, the density is high, and the shrinkage is large. Especially for the crystallized materials, the shrinkage is larger due to the high crystallinity and large volume change. The mold temperature distribution is also related to the internal and external cooling and density uniformity of the plastic parts, which directly affects the amount and direction of shrinkage of each part. In addition, maintaining pressure and time also has a large effect on shrinkage. When the pressure is large and the time is long, the shrinkage is small but the direction is large. Plastic mold manufacturers pointed out that the injection pressure is high, the viscosity difference of the melt is small, the interlaminar shear stress is small, and the elastic rebound is large after demolding, so the shrinkage can also be reduced appropriately, the material temperature is high, the shrinkage is large, but the directionality small. Therefore, factors such as adjustment of mold temperature, pressure, injection speed and cooling time during molding can also appropriately change the shrinkage of the plastic part. According to the shrinkage range of various plastics, the thickness and shape of the plastic part, the size and distribution of the feed port, the shrinkage rate of each part of the plastic part is determined empirically, and then the cavity size is calculated. Plastic mold manufacturers point out that for high-precision plastic parts and difficult to grasp the shrinkage rate, it is generally advisable to design the mold by the following method: 1 The outer diameter of the plastic part is taken to be smaller, and the inner diameter is taken to a larger shrinkage rate to leave room for correction after the test. 2 Plastic mold manufacturers pointed out that the test mold determines the form, size and molding conditions of the casting system. 3 The post-treatment plastic parts are post-treated to determine the dimensional change (the measurement must be made 24 hours after demolding. 4 The plastic mold manufacturer points out that the mold is corrected according to the actual shrinkage. 5 Re-test the mold and adjust the process conditions slightly to correct the shrinkage value to meet the requirements of the plastic parts.

How to design molds for plastic mold manufacturers

[ Previous] [Next] [Return] |